A small kiln for batch & continuous firing

Practical Action

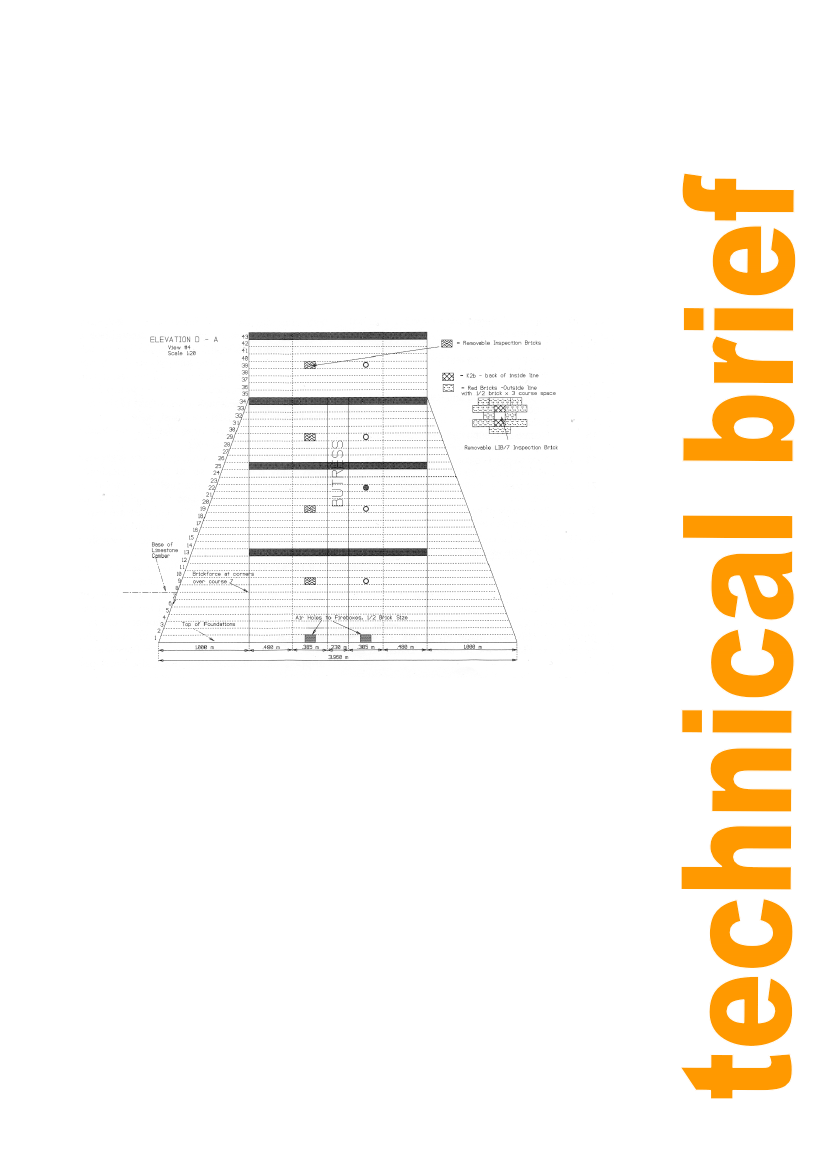

• Loading ports

The loading port shown midway up the kiln on elevation B-C is for the initial loading to reduce

work in loading the first half. For a kiln built in a hillside with a ramp for loading or if an

efficient hoist is used then it may not be very advantageous to use the top loading port.

• Fireboxes

Except where the fireboxes pass under the kiln walls, the bricks spanning the top of the

fireboxes form part of the floor of the kiln chamber. These bricks are adjusted to give the

maximum space for the fire to enter the chamber without allowing the unburned limestone to

fall through the gaps. The fixing of these bricks is exactly the same as for the firebars to allow

for easy replacement. There are 2 fireboxes and they run right through the kiln with the same

cross section as shown in the drawing (Elevation A–B). The fireboxes are built with standard

“heavy” firebricks.

• Firebars

Firebar spacing is approximately 100 millimetres. The “firebars” are standard firebricks

which rest on the bottom pairs of protruding bricks in each firebox. The size of the gaps

between the firebars can be adjusted depending on the fuel but for firewood we used gaps of

about 25 cm. Small pieces of brick bedded in a very low clay content mortar are placed on the

protruding bricks between the firebars to keep them in one place (See Elevation A–B). Gaps

should be left at the ends of the firebars to allow for expansion and for easy replacement when

the firebars break.

• Insulation

For insulation bricks, a few tests will show the maximum combustible material which can be

added to clay while still producing a brick strong enough to handle. Sieved sawdust is an ideal

combustible, but cereal husks or other chopped vegetable matter can also be used. Firing

insulation bricks needs a long soak at top temperature with a clean – smokeless – flame.

• Ring beams

The Ring Beams are cast as the wall is being built. When the correct course is reached the

outside 1⁄2 brick is left out all the way round and shuttering fixed level with the top of the

course. A single 6mm round bar, bent to shape and hooked together at the ends, is used for

reinforcement. It is placed in the middle of the brick vertically and approximately 1⁄4 way

across the brick from the outside wall horizontally (See detail in Elevation B–C). Provided the

concrete is kept damp for 10 days kiln building can continue 24 hours after placing the

concrete.

4